Our materials : Physical Properties

Assessment of chemical and physical properties of ceramics constitutes an essential step in their manufacture since they will decisively influence their final performances.

Solcera has a wide range of characterization techniques, from molecular to macroscopic scales

- Spectrometry

- Diffractometry

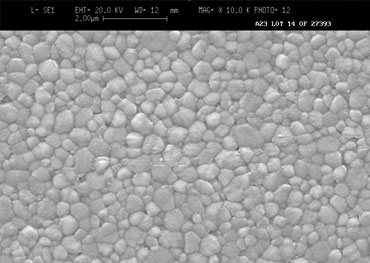

- Microscopy

- Laser diffraction analysis etc.

| Alumina | Zirconia | Nitrides | Boron carbide | Transparent materials | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Properties | Units | AF950 | TS150 | AF980 | AF997 | ZFME | ZFYT | Kersit | HP B₄C | MgF2 | Spinel | ZnS |

| Composition (mass %) | 95% Al₂0₃ | 97,6% Al₂0₃ | 98% Al₂0₃ | 99,7 % Al₂0₃ | 97% Zr0₂ | 95% Zr0₂ | 91% Si₃N₄ | 95% B₄C |

100% MgF₂ | 100% MgAI₂0₄ | 100% ZnS | |

| Density | g/cm³ | 3,60 | 3,75 | 3,89 | 3,89 | 5,70 | 6,00 | 3,20 | 2,50 | 3,18 | 3,58 | 4,09 |

| Hardness - Vickers | GPa | 15 | 15 | 15 | 18 | 11 | 13 | 16 | 28 | 6 | 13 | 2,9 |

| 3-point bending strength / biaxial (b) | MPa | 250 | 280 | 280 | 310 | 600 | 900 | 900 | 425 (4pts) | 130 | 390 | 95 (b) |

| Elastic modulus | GPa | 250 | 330 | 330 | 310 | 210 | 220 | 315 | 440 | 140 | 270 | 90 |

| Fracture toughness | MPa (m)¹/² | 3,8 | 3,8 | 4 | 4,8 | 8,5 | 10 | 7,5 | 3-4 | 2,2 | 0,6 | |

| Coefficient of thermal expansion | x10⁶ | 8,5 | 8,5 | 8 | 8,5 | 9,5 | 10 | 3,1 | 5 | 10 | 7,8 | 7,3 |

| Thermal conductivity (20° to 100°C) |

W/mK | 22 | 30 | 29 | 1,9 | 3 | 19 | - | 15,3 | 12 | ||

| Thermal shock resistance | ++ | ++ | + | + | +++ | ++ | +++ | + | ++ | + | + | |

| Maximum use temperature | °C | 1500 | 1700 | 1500 | 1700 | 2000 | 1000 | 1400 | - | 600 | 1500 | 200 |

| Electrical resistivity | Ohm.cm | > 10¹² | > 10¹⁴ | > 10¹⁴ | > 10¹² | > 10¹² | > 10⁷ | > 10¹⁰ | > 10⁷ | > 10⁷ | ||

This Chart is intended to illustrate typical properties of a selection of Solcera.

Property values may vary with method of manufacture, size and shape of part and may not be used as absolute values.

Typical properties of Solcera ceramics

Mechanical properties

High mechanical strength, low density, extreme hardness, toughness and great wear resistance.

Example :

Our boron carbide provides maximum ballistic protection efficiency with significant weight savings in military armor equipment.

Thermal properties

Our advanced ceramics remain stable even at very high temperatures, resist thermal shock and ageing and guarantee high resistance to climatic or chemical attack.

They show a low to moderate thermal conductivity and transparent / opaque properties other than for visible light.

Example :

Ceramic components for aircraft engines and propulsion systems for satellites. Magnesium fluoride infrared guidance windows for IR Seekers.

Electrical properties

Our ceramic components and hermetic ceramic-to-metal assemblies based on alumina guarantee optimal electrical insulation.

They are frequently used in high voltage applications with good dielectric strength, also called resistance to electrical breakdown.

Example :

Brazed high voltage electrical feedthroughs for medical imaging. Cathode and anode insulators for X-ray tubes.

Environmental characteristics

Ceramics are harmless to humans and eco-friendly due to their neutral and amorphous nature.

Example :

Hypoallergenic components based on zirconia for ceramic watches.

Our materials : Physical Properties

A project, do you need information or advice ?

Read moreContacts

- ZI N°1 - Rue de l'industrie

- 27000 EVREUX

- +33 (0)2 32 29 42 00

- 83 Rue Marcelin Berthelot

- 77550 MOISSY-CRAMAYEL

- +33 (0)1 64 13 61 10

- Contact