SOLCERA

SOLCERA

Please note the summer closing period

The Evreux site will close from August 4 to 15, 2025.

The Moissy site will close from July 28 to August 15, 2025.

We wish you all a very happy vacation!

Solcera

The ceramic experts

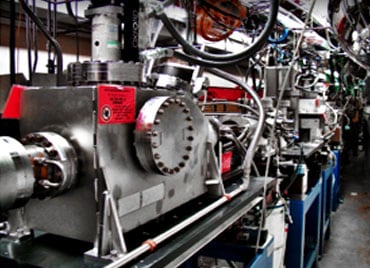

Solcera has been developing and marketing advanced ceramics, also called technical ceramics, for over 200 years.

Being an independent SME since 2015 with two facilities in France, a subsidiary in Brazil and another in Germany, as well as a sales office in Spain, our strategy relies on an extensive know-how in the design and manufacture of advanced ceramics as well as ceramic-to-metal and glass-to-metal assemblies.

We are developing a strong presence in cutting-edge industries such as aerospace, defense, nuclear, agriculture, optics and research.

We design and manufacture products that meet the most extreme application requirements:

- Corrosive and abrasive environments

- High temperature

- Electrical insulation

- High pressure

- High tension

- Cryogenics

- High-vacuum HV and ultra-high vacuum UHV reliability

Our values of respect, cooperation and responsibility are shared by all of our employees and guide the relationships with all of our partners, customers and suppliers.

SolceraNEWS

INTERNATIONAL AERONAUTICS AND ESPACE EXHIBITION LE BOURGET - Paris

SOLCERA's President, Mr. Lisle, was honored to stand alongside the French Prime Minister, Mme Elisabeth BORNE, during her visit to the International Paris Air Show.

We would like to thank NAE (Normandie AeroSpace) for their excellent organization of the Paris Air Show!

Next exhibition for 2025 : June 16 to 22, 2025

Hall 2b - Stand : DE64 - Paris, le Bourget / France

Trade fair diary

Materials

Selection Guide

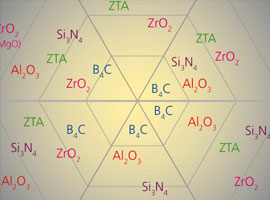

The selection of ceramic materials rather than metals or polymers is related to their exceptional properties for use in extreme conditions and strict requirements: temperature, pressure, wear, corrosion, high voltage, vacuum, UHV, even several conditions may occur simultaneously or over an extended period.[...]

Physical Properties

Assessment of chemical and physical properties of ceramics constitutes an essential step in their manufacture since they will decisively influence their final performances. [...]

Solcera has a wide range of characterization techniques, from molecular to macroscopic scales

Spectrometry

Diffractometry

Transparent ceramic

Unlimited imagination in design

An innovative spinel material in defense, security and personal protection (ballistic protection, opto-electronics, pods, optical imaging, sensors, IR countermeasures), in optics photonics (windows, lenses, prisms, freeform optics, wafers) and in luxury (watchmaking, jewelry and [...]

INNOVATION AS A CORE COMPETENCE

Solcera provides technical support and co-development skills right from the system design stage. We are proactive in finding solutions to validate new ideas and products in line with our customer’s specific requirements.

Long-term partnerships with major private and public players, the constant transmission of work experience and our innovation focused R&D team are all key ingredients to ensure our future business growth and the preservation of the company’s know-how.

Our facilities are vertically integrated in order to provide complete control over the entire manufacturing process: powder preparation, shaping, heat treatment, machining, assembly and inspection. The production of prototypes, as well as small and medium-size series is carried out by our specialists whose broad expertise and know-how make the success of our company.

Quality at the service of performance

Solcera promotes a complete quality approach to its customers, employees, suppliers and service providers.

In order to support our strategy of sustained and sustainable growth, the Solcera Management Committee is committed to :

- Promote our values: respect, responsibility, cooperation

- Put customer satisfaction at the heart of all our activities

- Deploy a continuous improvement plan with all employees, suppliers and subcontractors

- Ensure full compliance with all legal and customer requirements

A project, do you need information or advice ?

Read moreContact

- ZI N°1 - Rue de l'industrie

27000 EVREUX - +33 (0)2 32 29 42 00

- ---------------------------------

- 83 Rue Marcelin Berthelot

77550 MOISSY-CRAMAYEL - +33 (0)1 64 13 61 10

- Contact